-

- Minimize or eliminate the need to put personnel in the dry cavity for manual brushing, thereby reducing personnel dose exposure.

- Reduce critical path time by conducting the decon while flooded, allowing fuel movement and other tasks to continue uninterrupted.

- Improve cleaning coverage

Flexible Mobility For Maximum Efficiency

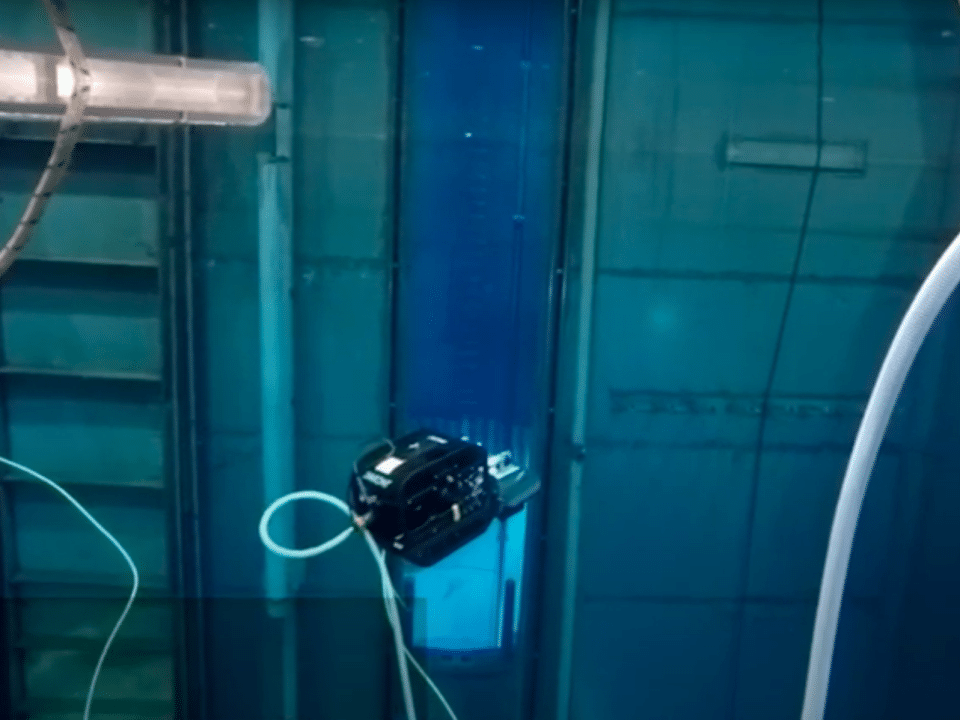

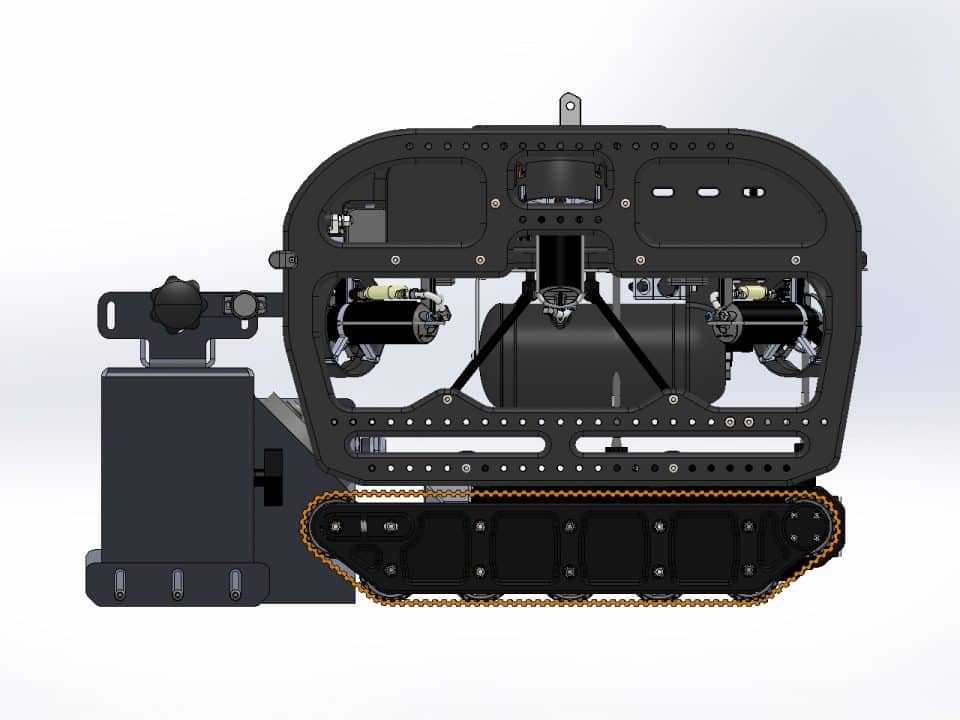

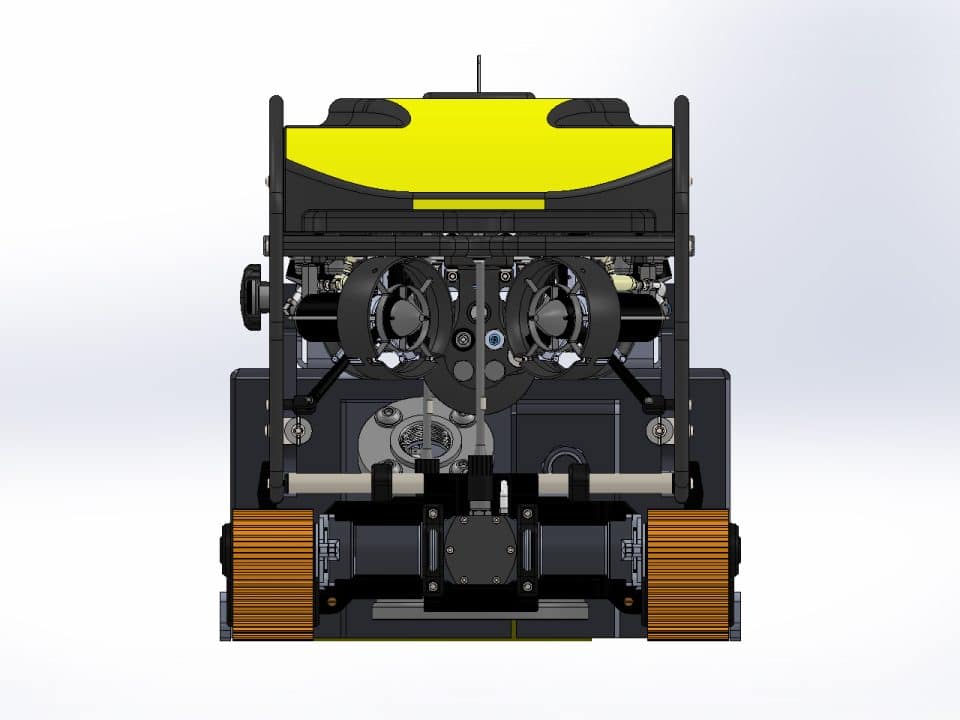

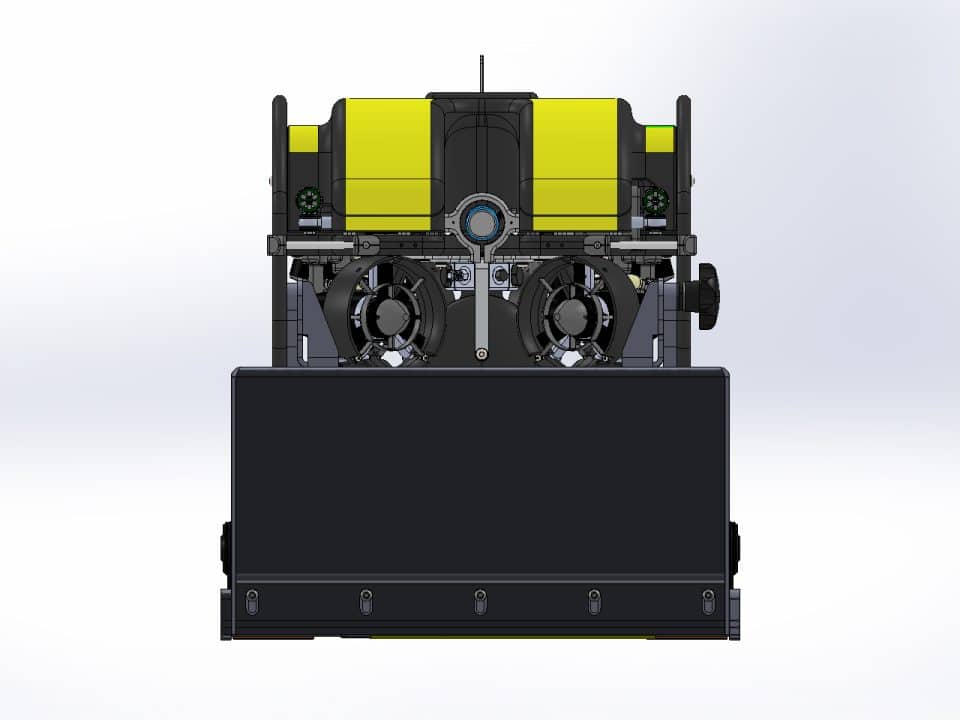

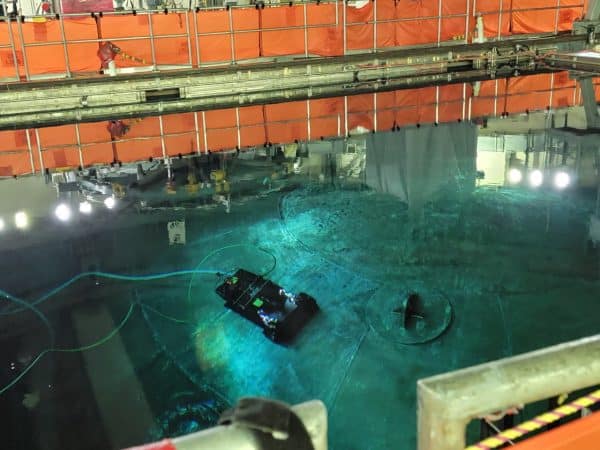

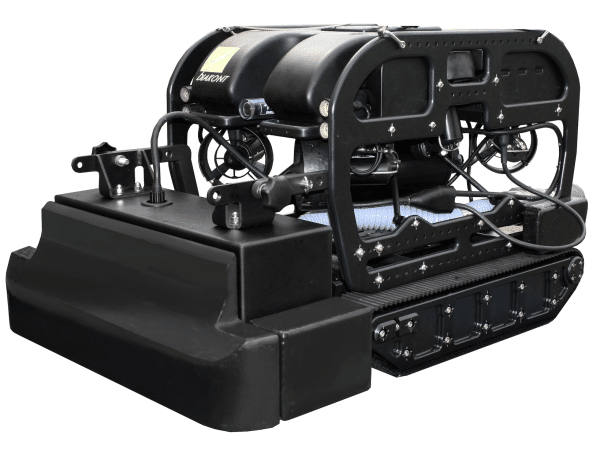

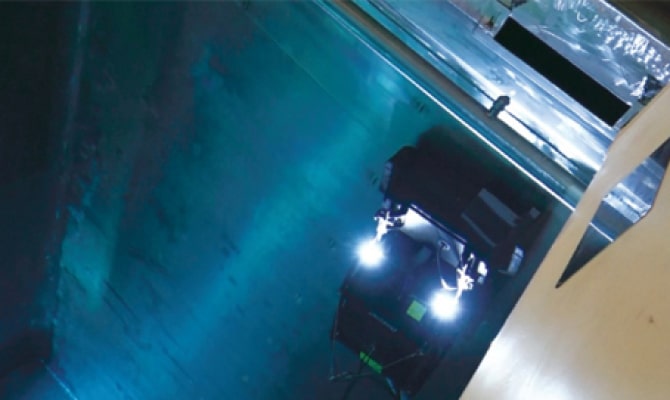

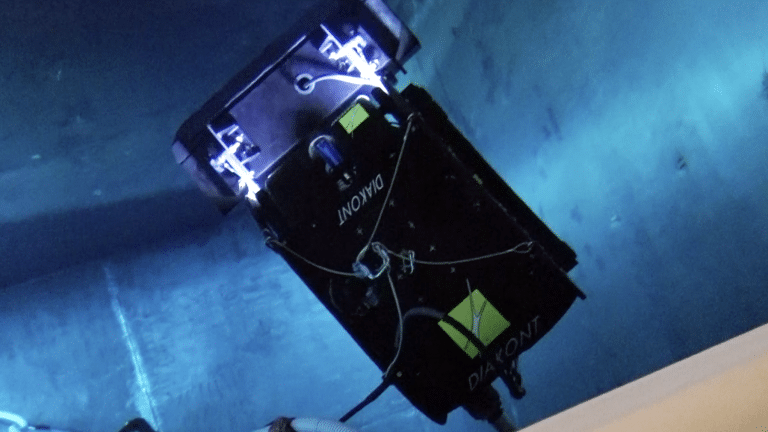

This hybrid Remotely Operated Vehicle (ROV) has an integrated cleaning system run by a small team of Diakont field technicians. These technicians stay at the control station located at the perimeter of the refueling floor. Once prepared for launch, a technician stands at the side of the cavity and belays the robot down using its umbilical. This innovative tool transitions seamlessly between an ROV “flying” and a cleaning “crawler” mode for maximum flexibility and bridge-free operation. No adjustments are needed during the process, even when transitioning between cleaning cavity floors, walls, and complex shapes such as a drywell.

The ROV uses a high-force, no-flow vortex generator to attach and drive along the cavity’s surfaces. Operation continues even in the presence of the Residual Heat Removal System (RHR) or shutdown cooling flow. With the utmost efficient and effective cleaning design, the tool utilizes rugged brushes to detach the crud from cavity surfaces. The debris is then vacuumed into a submerged filter at a high flow rate.

-

Ideal Applications Within Nuclear Power Plants

- Reactor Cavity

- Drywell heads and other curved surfaces

- Equipment pools and pits

- Spent fuel pools

- Cask loading pools

- Fuel transfer canals

Purposeful Design, Build, & Execution

This tool leverages mature, nuclear-proven, FME-compliant modules while meeting or exceeding EPRI and industry-standard FME guidelines for nuclear plants.

Let's Work Together