-

- Time saving: Inspect all four sides of fuel assemblies simultaneously

- No impact: Inspection performed off critical path

- Proven technology: Based on Diakont’s state-of-the-art D40 rad-tolerant camera systems

- Versatile control: PTZ camera control for bottom nozzle inspection

- Tailored to fit: Customizable installation to meet any plant configuration

High Efficiency Fuel Assembly Inspection

-

The Process

Installed during routine fuel transfers (refueling cavity to the spent fuel pool), the FAIS is placed in the transfer canal near the upender (in the spent fuel building). It is then positioned directly above the upender, with each camera oriented perpendicular to the four faces of the fuel assembly. The inspection begins once the fuel is extracted from the upender. There is zero impact (in added time or motion) on the fuel transfer operation.

High Quality and Reliability

One of the four D40 cameras is installed on a pan/tilt mount for remote manipulation and viewing on the bottom nozzle. The D40 camera system has won popularity among nuclear power plant builders, contractors, and operators worldwide, making it the ideal solution for fuel inspection applications. Thousands of systems have been deployed in the United States, Japan, France, Finland, and other countries.

Technical Specifications

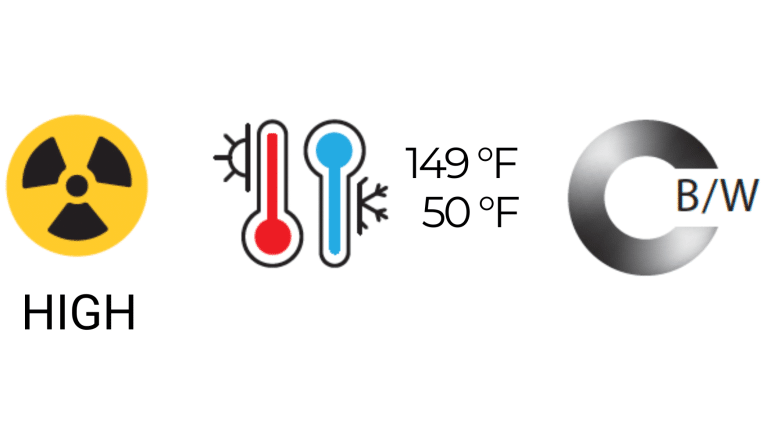

Camera Tube 2/3” E-Chalnicon Resolution 600+ H-TVL Signal/Noise Ratio ≥ 46 dB Sensitivity 16 lux Zoom 2x analog (10:1 option) Iris Auto / Remote; F/1.4 to 16 Cumulative Dose 5*108 Rads Maximum Dose Rate Up to 3*106 Rads/hr Lights Integral, LED Housing Stainless Steel Protection IP 68, 40m submersible Let's Work Together